Product Details

Product Introduction

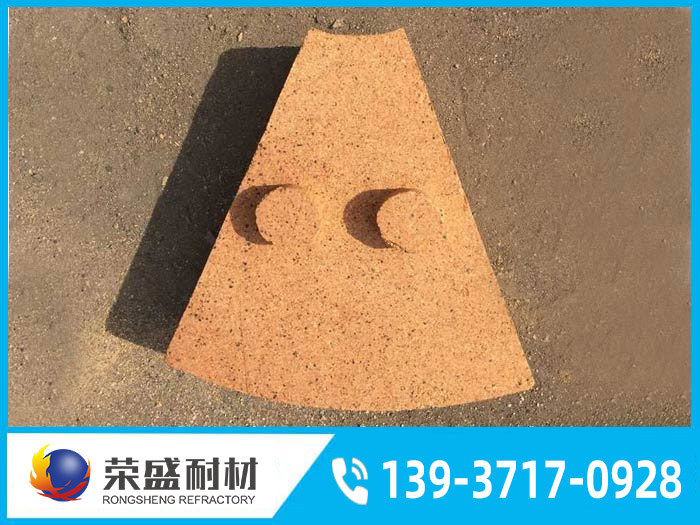

Rongsheng high-performance clay refractory bricks are classic refractory products, made of high-quality soft clay and hard clay clinker according to a specific particle size ratio, mixed with refractory clay as a binder. The Al2O3 content of this product is between 30-48%, and it is sintered at a high temperature of 1300 to 1400℃, showing good resistance to rapid cooling and heating and stable thermal performance. As a weakly acidic refractory material, it mainly resists the erosion of acidic slag and acidic gas, and also has a certain tolerance to alkaline substances. Rongsheng clay refractory bricks are widely used in a variety of high-temperature equipment, such as thermal boilers, glass kilns, cement kilns, gasification furnaces, blast furnaces, etc., to ensure their efficient operation and structural safety. The product classification is rich, including fan-shaped clay bricks and other special-shaped bricks, etc., to meet the specific needs of different equipment. With continuous technical research and development and intelligent manufacturing processes, the products have international quality and durability, and are the preferred materials for domestic and foreign customers in high-temperature environments.

Advantages and features

1. High-quality raw materials ensure resistance to rapid cooling and heating, and provide stable thermal stability; 2. High aluminum content (30-48% Al2O3) ensures excellent thermal performance and corrosion resistance; 3. High-temperature sintering at 1300 to 1400℃ ensures high durability and lasting strength; 4. Diversified product forms adapt to complex kiln structures and special working conditions; 5. Compliance with international quality standards ensures wide applicability to global customers.

Application Scenario

1. Thermal facilities: thermal boilers, gas generators, etc.; 2. Metallurgical industry: blast furnaces, cement kilns, glass kilns, etc.; 3. Special-shaped bricks can be customized on demand to meet the specific needs of diverse kilns.