Product Details

Product Introduction

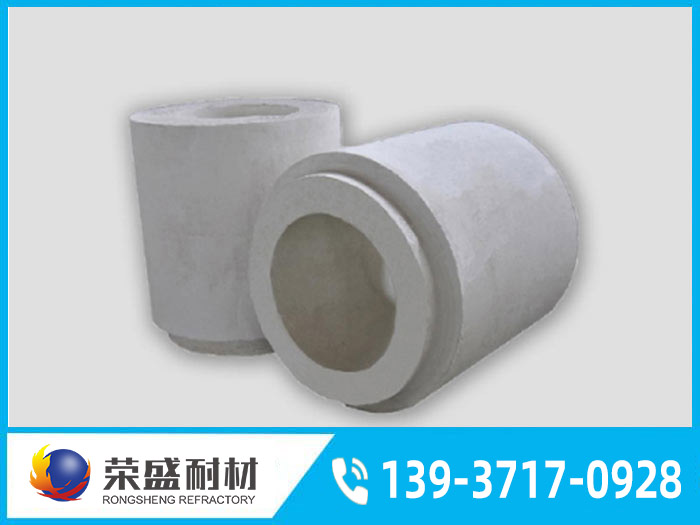

The nozzle seat brick is a high-performance refractory material made of high-purity raw materials, through vibration casting and low-temperature baking process. Its main features include high hot strength, strong thermal shock resistance, excellent erosion and scouring resistance, and hot repairability. These properties enable the nozzle seat brick to work stably for a long time under high temperature and harsh operating conditions, and are widely used in the metallurgical field, such as the seat brick device of the ladle air brick. Its high-temperature erosion resistance enables it to resist the erosion caused by acidic and alkaline slag during the molten steel smelting process; high-temperature wear resistance ensures durability under forced stirring conditions; good spalling resistance enables it to maintain structural stability when the temperature changes drastically. At present, this product has been successfully applied in Shagang, Huaigang, Henggang and other units, effectively improving the service life and safety performance of ladle air bricks, and becoming a key functional refractory material in high-temperature processes.

Advantages and features

1. Made of high-purity raw materials, vibrating casting and low-temperature baking process to ensure high performance. 2. High hot strength, able to remain strong and stable in high temperature environment. 3. Excellent thermal shock resistance, adaptable to rapid temperature changes. 4. Excellent corrosion and erosion resistance, able to cope with acidic and alkaline slag corrosion during steelmaking. 5. Support hot repair function, easy maintenance and extended service life.

Application Scenario

1. Widely used in metallurgical fields, such as the base brick device of ladle air bricks. 2. Suitable for industrial high temperature operating environments that require high temperature corrosion resistance and wear resistance.